How to determine freight class

Overview

The freight transportation system is one of the largest industries in the United States, both in terms of scope and economy. According to the U.S. Department of Transportation, freight transportation directly affects more than 44 million jobs in the country, which is nothing to say of the millions of homes and businesses that require freight for everyday survival.Freight transit is an expanding industry, with estimates suggesting a 45% increase in freight tonnage by the year 2040. That equates to about 9 billion tons of total freight added to the already massive 54 million tons of daily freight that’s currently shipped throughout the country.

Many businesses have turned to less-than truckload (LTL) freight shipping as a means of saving on shipping costs without sacrificing quality of service, but one of the biggest difficulties for new businesses is understanding freight class. Read on to learn about the meaning of LTL shipping, the importance of freight class, how you can determine the freight class of your shipments, and why shared truckload shipping doesn’t require freight class.

What is LTL shipping?

LTL shipping is, in its most basic sense, shipping less than a truckload of freight in a trailer, as opposed to moving a full truckload of freight, which is known as truckload (TL) shipping. With LTL service, you share trailer space with other businesses that are sending goods, allowing the carrier to fill a truck to capacity with the freight of multiple shippers. Shippers only pay for the space that their respective freight takes up, making LTL a more affordable shipping solution than truckload services.

Unlike other forms of shipping, LTL freight moves through a hub-and-spoke model. In this model, local terminals act as spokes that connect to central hubs or distribution centers. At local terminals, workers load freight onto trucks. Then, a driver takes the freight to the distribution center for either delivery or consolidation into other trailers for further transit. In contrast, TL shipping generally works in a Point-A-to-Point-B system with few stops in between. Often, LTL shipping entails more handling than TL shipping.

What is freight class?

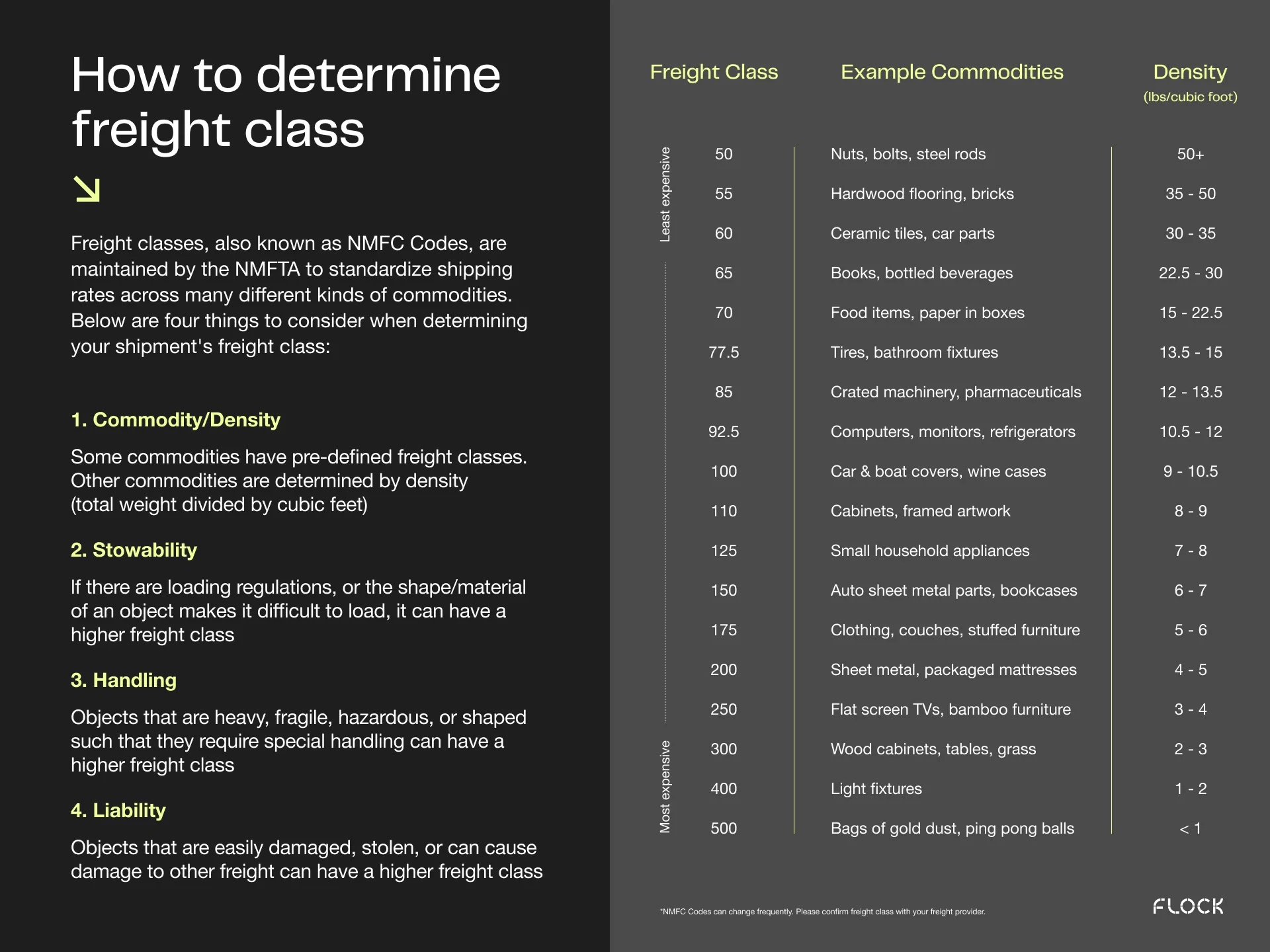

Freight class is a measurement that allows for standard prices across all LTL freight carriers and businesses. The National Motor Freight Traffic Association (NMFTA) determines freight classes. Generally, every type of product or commodity has a National Motor Freight Classification (NMFC), which corresponds to a specific freight class number for LTL shipments. Freight class generally ranges from 60 to 400 and is based on specific types of commodities. For example, refrigerators belong to Class 92.5, while cabinets are categorized as Freight Class 110.

LTL freight carriers care about freight class because it determines tariffs that they must pay to transport goods. This, in turn, determines shipping rates and fees. Unfortunately, many businesses will underestimate freight class or declare an incorrect freight class. While it may seem smart to list a lower freight class to save money, the carrier may need to re-class your freight, which causes delays and can result in wasted money, time, and resources. In many cases, freight class also corresponds to the size of a shipment. Carriers must understand the size of each shipment to optimize trailer space.

Factors that determine freight shipping class

Commodity and density

Some commodities are not based on density and have pre-defined freight classes. However, other commodities are density-based. This is determined by the total cubic feet divided by total weight in pounds. Freight with a lower density results in a higher freight class.

Stowability

Assuming you have packed it properly, most freight should be fairly easy to stow in trucks, trains, boats, and planes. However, some items are regulated by the government or can’t be loaded with other items. Freight that is excessively heavy, is too long, or has odd protrusions can be difficult to load, especially with other shipments. Shipments should also have clear load-bearing surfaces to make them easier to stack with other freight. Essentially, if an item is difficult to load, it will have a higher freight class, which will increase the overall shipping cost.

Handling

Freight goes through various checkpoints and distribution facilities before it reaches its final destination, and a properly packed shipment generally shouldn’t run into any problems. While equipment can load most freight without issue, items that are hard to stow and goods that are heavy, fragile, awkwardly shaped, or hazardous require special handling to prevent damage or harm to workers and other freight. The carrier may categorize freight that’s more difficult to load or carry as a higher freight class.

Liability

Liability refers to the probability that any piece of freight may be stolen, damaged, or damaging to other freight in its proximity. For example, perishable cargo or freight that may be prone to sudden explosion or combustion is a higher liability, which is valued per pound.

Understanding density-based freight class

Assuming that your freight doesn’t have any significant liability, handling or stowing problems, density ends up being the main determining factor for freight class. The Commodity Classification Standards Board developed guidelines for determining freight class based on the density of a shipment. These guidelines assume an average density among all commodities within a freight class, ignoring any problems with stowing, handling, and liability.

Many LTL freight carriers often opt for density-based freight class because commodity freight class can be arbitrary. For example, not all computer monitors weigh the same, but they would all be grouped in Freight Class 92.5. While that might make sense if you are a big-box manufacturer that produces several truckloads of the same computer monitor, it can become incredibly arbitrary, especially because LTL carriers often consolidate several different shipments from businesses. Going by true density eliminates potential arguments between carriers and shippers over interpretations of commodity NMFC class codes in the NMFC manual. With that said, handling and liability can still affect your shipping rates outside of freight class.

How to calculate your freight density

- Measure the length, width, and height of your shipment. Remember that this measurement includes pallets and other packaging around the actual shipment. Round up to the next inch. You will have to repeat this step for shipments that have multiple pieces or pallets.

- Multiply the height, width, and length measurements you just took. This gives you the total cubic inches of the shipment. Divide this number by 1,728 to convert cubic inches to cubic feet. If you have several different pieces, multiply the length, width, and height of each individual piece. Add the cubic measurements for each individual piece together to get the total, then convert to cubic feet if necessary.

- Determine the weight of the shipment in pounds. Divide the weight by the total cubic feet of the shipment to get the pounds per cubic foot, or density. For multiple pieces, add the total weight of each piece before dividing by the total cubic feet.

- Once you have the freight density, use the following LTL freight class chart to determine the freight class.

Freight class codes chart

Remember that these are estimates and only apply to carriers that base their freight classifications on density alone. Some LTL carriers have their own specific guidelines for determining freight class. However, assuming you have measured your shipments properly, you should have a fairly accurate idea of your freight classification. Alternatively, you could use a freight class calculator.

Preparing your goods for LTL shipping.

Determining your freight class is just the first step in preparing your shipment for your LTL carriers. Through proper preparation, you can prevent bottlenecks, save money, and ensure that your freight reaches its destination on time and free of damage.

Make sure you have your shipment documentation on hand. Documentation mainly comprises the bill of lading, which acts as a contract between you and your carrier. It should also provide all the information that the carrier, the driver, and any workers down the line need to process and invoice the freight. A typical bill of lading includes:

- Name and information of the recipient

- Date of shipment

- Description of the packaging type

- Description of the goods that are being shipped

- Number of units that are getting shipped

- Dimensions

- Freight class

- Estimated value

You should also load your shipment onto pallets or crates before pickup. Place lighter items on top of heavier items and include at least one label on every unit to prevent any potential losses. Use appropriate labels for any items that are fragile, hazardous, or require special care. Remember that the LTL shipping process often means that workers handle freight several times throughout transit. Providing a proper label can prevent damages and give workers and drivers a better idea of how to move shipments.

Once you have your shipment ready, your LTL carrier can pick your freight up and send it on its journey. You should have the bill of lading and all the necessary information in hand when the carrier arrives. Keep in mind that LTL carriers do not have the luxury of long loading windows. While TL carriers often allow a two-hour window to load goods, LTL carriers are not required to wait. If your shipment isn’t ready, LTL carriers will leave and come back the next day, which delays delivery and usually leads to a second-day pickup fee.

Flock Freight is dedicated to changing the LTL shipping experience for small- to medium-sized businesses. We provide more affordable rates, while increasing safety and security so businesses don’t have to worry about damage.

Avoid freight class confusion with shared truckload service.

Like TL shipping, Flock Freight’s shared truckload solution removes the need for freight class altogether. Because the company bases the price of its shared truckload service on linear feet and a derivative of each lane’s TL rate per mile (RPM), freight class is irrelevant. The truck helps determine the figure for linear feet, while the market dictates each lane’s truckload RPM. Shippers win because they only pay for the space they need (the “shared” rate), as opposed to the rate of the whole truck. With Flock Freight’s shared truckload solution, shippers can unlock the benefits of TL service for a fraction of the pric